The Ultimate Guide to Selecting Your Next Laser Cutting Machine

Investing in a new Laser Cutting Machine is a significant decision for any metal fabrication business. With the market flooded with options—from High-Power Fiber Laser Cutting Machines to specialized Tube Laser Cutting Machines—making the right choice can feel overwhelming. This guide will walk you through the key considerations, helping you match the perfect machine from a leading manufacturer like DNE Laser to your specific production needs.

Step 1: Define Your Primary Material and Application

The first and most crucial step is understanding what you'll be cutting most often. This directly dictates the type of machine you need.

- Sheet Metal Dominated Work: If your shop primarily handles flat sheets for enclosures, panels, or brackets, a flatbed Sheet Metal Processing Equipment is your starting point. For high-volume production, consider integrating it into a Sheet Metal Processing Production Line with automation. DNE Laser's D-Speed series is engineered for High-Speed Cutting of thin to thick sheets, maximizing throughput.

- Tube and Profile Fabrication: For businesses focused on structural components, furniture, or automotive frames, a dedicated Laser Tube Cutting Machine is non-negotiable. Look for models capable of handling Round Tube, Square Tube, and even Thin-Wall Tube Laser Cutting. The D-Tube 360 from DNE, for instance, offers exceptional versatility for complex Steel Tube Cutting.

- Mixed-Material & High-Precision Jobs: Shops working with a variety of metals, including challenging materials like aluminum or copper, require a robust Precision Metal Laser Cutting Machine. A High-Power Fiber Laser Cutting Machine (like a 12kW or 15kW model) provides the flexibility and cutting edge quality needed for diverse Laser Processing and Cutting tasks.

DNE Laser's D-Tube 360: A prime example of a versatile High-Speed Tube Laser Cutting Machine designed for precision cutting of various profiles.

Step 2: Evaluate Power and Performance Requirements

Laser power (measured in kW) is a primary driver of capability, speed, and operational cost. It's not just about raw power, but the right power for your materials.

| Laser Power | Ideal For | Key Benefit | DNE Laser Model Example |

|---|---|---|---|

| 3kW - 6kW | Mild steel up to 15mm, stainless steel, Aluminum Laser Cutting (thinner gauges). Great for job shops. | Excellent balance of speed and quality for common thicknesses; lower initial investment. | D-Soar Plus series |

| 8kW - 12kW | Heavy plate cutting (20mm+), high-speed piercing, and improved cutting quality on reflective metals. Ideal for High-Efficiency Fiber Laser Cutting. | Dramatically increased throughput on thicker materials; reduced cost-per-part. | D-Power, D-Giant F series |

| 15kW+ | Extreme thickness cutting, shipbuilding, mining equipment. The pinnacle of High-Power Fiber Laser Cutting Machine technology. | Unmatched cutting speed and ability to process very thick plates in a single pass. | D-Energy F series |

Remember, a higher-power machine isn't always better if you're only cutting thin gauge material. It can lead to unnecessary energy consumption. Consulting with an expert from DNE Laser can help you pinpoint the optimal power range.

Step 3: Consider Advanced Features and Automation

Modern Laser Cutting Machines for Metal Fabrication are packed with features that boost productivity and ease of use.

- Bevel Cutting Capability: For welding preparation, the ability to perform ±45° Bevel Cutting directly on the laser is a game-changer, eliminating secondary operations. This is a hallmark of advanced Specialized Cutting Machines.

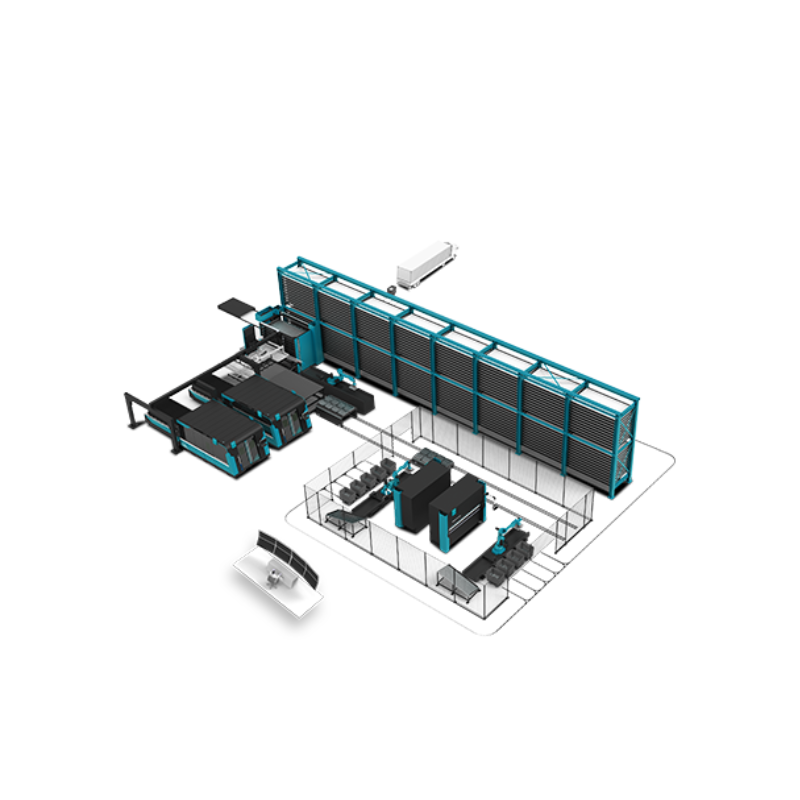

- Automation Integration: To maximize uptime, look for machines designed for automation. DNE Laser's D-Trans automatic loading/unloading systems and their comprehensive Smart Factory Solution can transform a standalone machine into a continuous production cell.

- Software and Control: A user-friendly CNC system is vital. Ensure the machine's software supports efficient nesting, easy program management, and perhaps even remote monitoring.

Step 4: Assess Build Quality, Support, and Credentials

This is where choosing a reputable manufacturer like DNE Laser pays long-term dividends. Don't just look at the price tag.

- Manufacturer Pedigree: As a wholly-owned subsidiary of the Swiss Bystronic Group, DNE Laser combines global engineering excellence with deep local manufacturing expertise in Foshan, China. This blend often results in a more cost-effective alternative to fully Imported Laser Cutting Machines without sacrificing quality.

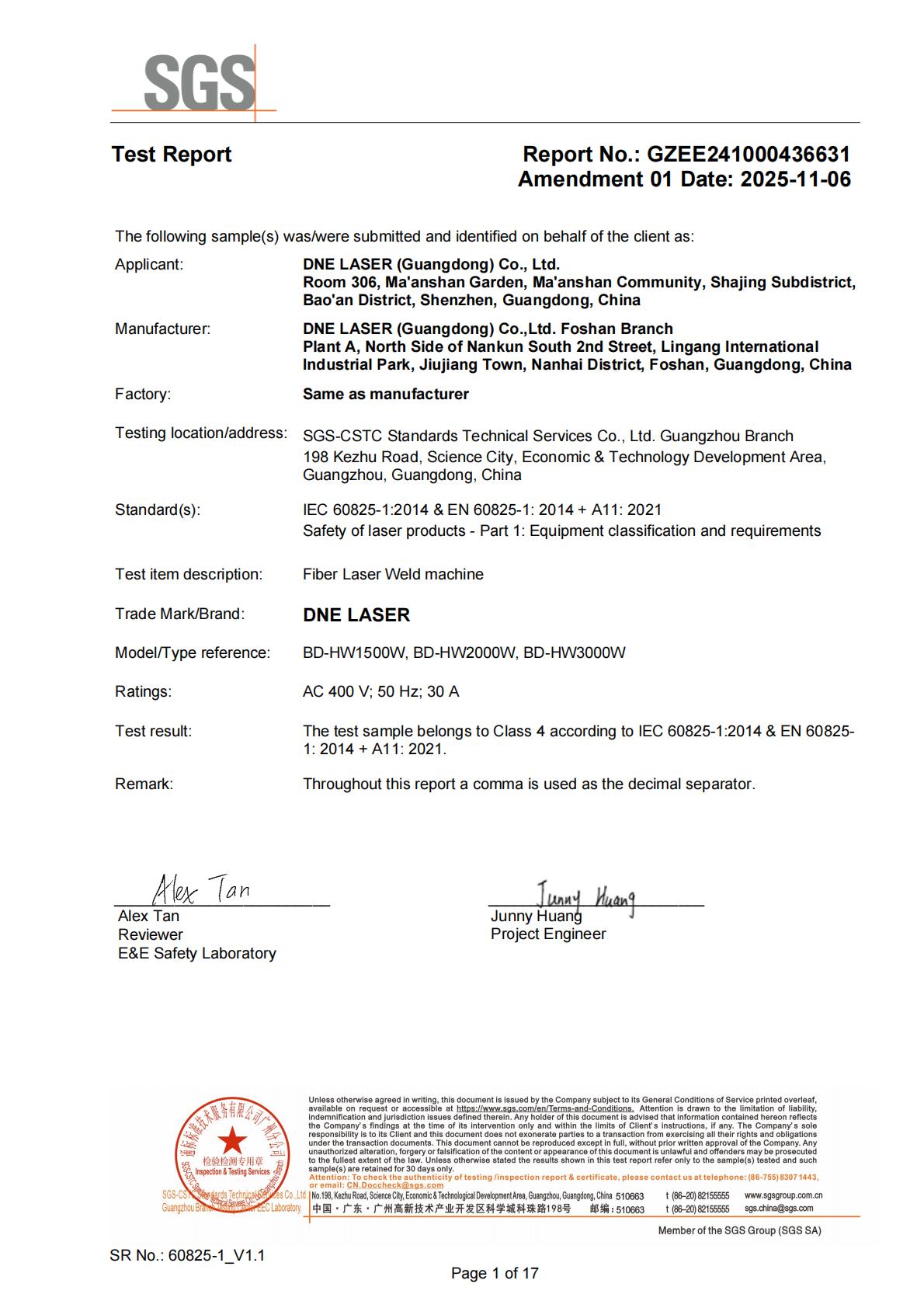

- Certifications and Awards: These are tangible proofs of quality and reliability. DNE Laser holds multiple SGS Certificates, is a National High-Tech Enterprise, and operates the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines. Their status as a "Specialized, Refined, Distinctive, and Innovative" (SRDI) Enterprise speaks volumes about their focus.

- After-Sales Service Network: Ensure the supplier has a robust service team, readily available spare parts, and comprehensive training. DNE Laser's recognition as an "Outstanding Localization Service Provider" is a key indicator of their commitment to customer support.

Making Your Final Decision

After narrowing down your options, request material sample cuts on your specific thicknesses and materials. Compare cut quality, edge smoothness, and speed. Evaluate the total cost of ownership, including energy consumption, consumable costs, and potential financing options.

For businesses seeking a reliable partner that offers everything from a standard 3/6/12kW Laser Cutting Machine to fully automated Sheet Metal Processing Production Lines, DNE Laser presents a compelling choice. Their portfolio addresses the full spectrum of Laser Cutting needs, backed by solid credentials and a clear vision for intelligent manufacturing.

Ready to discuss your specific requirements? Contact the DNE Laser team today for a personalized consultation.

Email: eva.fu@dne.global | WhatsApp/Phone: +86 137 0275 1410

Website: https://www.dne.global