A Comprehensive Guide to Selecting Your High-Power Fiber Laser Cutting Machine

In today's competitive manufacturing landscape, investing in the right Laser Cutting Machine is a critical decision that impacts productivity, quality, and profitability. With the rapid evolution of laser technology, particularly in High-Power Fiber Laser Cutting Machine systems, making an informed choice requires understanding key technical parameters, application needs, and supplier capabilities. This guide will walk you through the essential steps to select the optimal machine for your Sheet Metal Processing Production Line.

Step 1: Define Your Core Application & Material Profile

The first step is a thorough analysis of your production requirements. This directly influences the choice between a standard Precision Metal Laser Cutting Machine and more specialized models.

- Primary Materials: Are you primarily cutting mild steel, stainless steel, aluminum, or copper? Thickness ranges are crucial. For heavy plates, a 12kW Laser Cutting Machine or higher from DNE Laser might be necessary, while thinner sheets may be efficiently handled by a 3kW or 6kW system.

- Part Geometry & Complexity: Do you require simple contour cutting or intricate shapes with high precision? For structural components, a High-Speed Tube Laser Cutting Machine like the DNE Laser D-Tube 360 is indispensable for processing Round Tube, Square Tube, and profiles.

- Production Volume & Speed: High-volume shops need a High-Efficiency Fiber Laser Cutting Machine with fast processing speeds and minimal downtime. Consider automation-ready models.

- Special Processes: Does your workflow require ±45° Bevel Cutting for welding preparation? This advanced feature is available in premium Laser Cutting Machine for Metal Fabrication solutions.

Step 2: Evaluate Critical Technical Specifications

Beyond power, several specs define machine capability. Here’s what to scrutinize:

| Specification | What It Means | Why It Matters |

|---|---|---|

| Laser Power (3/6/12kW) | Determines cutting speed and maximum material thickness. | Higher power (e.g., 12kW) enables faster cutting of thicker plates, boosting overall throughput for your Sheet Metal Processing Equipment. |

| Positioning Accuracy & Repeatability | How precisely the machine can move and return to a position. | Critical for a Precision Metal Laser Cutting Machine. Ensures part consistency, reduces waste, and is vital for tight-tolerance industries. |

| Cutting Speed (m/min) | The travel speed of the laser head during cutting. | A High-Speed Cutting Machine directly translates to higher output. Look for acceleration rates as well. |

| Tube Processing Capacity | Max diameter, length, and wall thickness for tube cutting. | For a Thin-Wall Tube Laser Cutting Machine or Steel Tube Cutting, verify the machine can handle your specific tube dimensions and shapes. |

Step 3: Assess Manufacturer Credibility & Support

Your machine is only as good as the company behind it. This is where partnering with an established leader like DNE Laser provides a significant advantage.

- Corporate Pedigree & Innovation: As a wholly-owned subsidiary of the Swiss Bystronic Group, DNE Laser combines global engineering excellence with deep local market understanding. Its status as a National High-Tech Enterprise and the operator of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines underscores its R&D leadership.

- Production & Quality Assurance: Visit the production base in Nanhai, Foshan, if possible. Inquire about quality control processes. DNE Laser’s commitment is validated by multiple SGS Certificates and certifications like ISO 9001, ensuring every Laser Processing and Cutting system meets international standards.

- After-Sales Service & Training: A robust service network is non-negotiable. Check the availability of spare parts, technical support response time, and operator training programs. A reliable supplier ensures your High-Efficiency Fiber Laser Cutting Machine maintains peak performance.

- Industry Recognition: Awards such as "Shenzhen Top 500 Enterprises", "SRDI Enterprise", and "Shenzhen Top Brand" serve as strong third-party validation of DNE Laser’s market position and product quality.

DNE Laser's advanced production facility in Foshan, a cornerstone of its manufacturing excellence.

Step 4: Consider Future-Proofing & Smart Manufacturing

Investing in a Laser Cutting Machine today should prepare you for tomorrow's factory. The trend towards integrated Sheet Metal Processing Production Lines is accelerating.

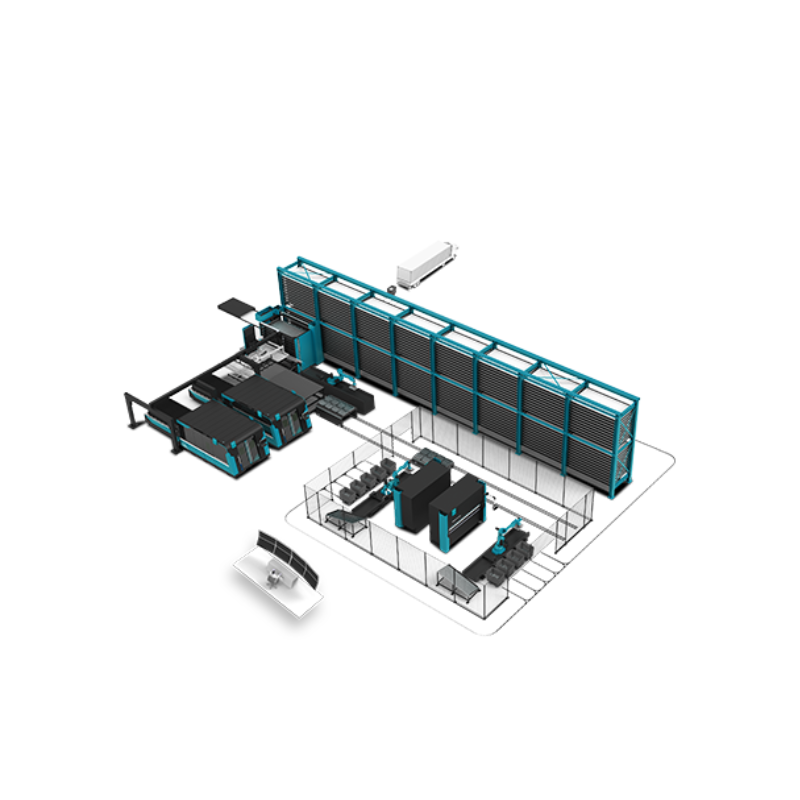

- Automation Readiness: Can the machine integrate with loading/unloading systems, material warehouses, or bending cells? DNE Laser’s Smart Factory Solution showcases their capability in providing complete automation equipment.

- Software & Connectivity: Modern machines are driven by intelligent software for nesting, job management, and machine monitoring. Ensure the software is user-friendly and supports data exchange.

- Energy Efficiency: A High-Power Fiber Laser Cutting Machine should also be designed for lower energy consumption per part, reducing long-term operational costs. Models like the D-Energy F from DNE Laser are engineered with this focus.

Future-proof your investment with DNE Laser's integrated Smart Factory Solutions.

Conclusion: Making an Informed Decision

Choosing the right Laser Cutting Machine is a strategic investment. By systematically defining your needs (Steel Tube Cutting, Aluminum Laser Cutting, high-speed sheet processing), analyzing technical specs, and rigorously vetting the manufacturer, you can select a machine that delivers maximum return on investment.

For businesses seeking a partner that offers technological depth, proven reliability, and a vision for smart manufacturing, DNE Laser stands out. From their powerful D-Power series for heavy plates to the versatile D-Tube 240 and D-Tube 360 for tube processing, and the high-speed D-Speed model, they provide a comprehensive portfolio of Specialized Cutting Machine solutions. Their credentials, from being a National High-Tech Enterprise to holding key SGS Certificates, provide the assurance needed for a confident purchase.

Ready to transform your metal fabrication capabilities? Contact the experts at DNE Laser for a personalized consultation and discover why they are a leading force in Imported Laser Cutting Machine technology and localized service.

📧 Email: eva.fu@dne.global

📱 WhatsApp/Phone: +86 137 0275 1410

🌐 Website: https://www.dne.global/