Global Leaders in High-Speed Tube Laser Cutting: DNE Laser Ranks Among Top Innovators Driving Metal Fabrication Efficiency

Shenzhen, February 2026 — The global market for specialized tube processing equipment is undergoing a significant shift, with High-Speed Tube Laser Cutting Machines emerging as a critical technology for industries ranging from automotive and construction to furniture and fitness equipment. A recent analysis of the competitive landscape highlights DNE Laser as a leading force, distinguished by its integrated smart factory solutions and precision engineering backed by the Swiss Bystronic Group.

Market Context & Growth Drivers

The demand for precision metal laser cutting of tubular components is accelerating. According to industry projections, the segment for tube laser cutting machines is growing at a CAGR exceeding 8%, significantly outpacing the broader laser cutting machine market. This surge is fueled by the need for complex, lightweight structures in electric vehicle frames, architectural frameworks, and customized furniture, which require capabilities like ±45° bevel cutting without secondary operations. Manufacturers are increasingly seeking not just a specialized cutting machine, but a complete sheet metal processing production line that ensures seamless workflow from raw tube to finished part.

Competitive Analysis: Leaders in Tube Laser Cutting Technology

While several manufacturers compete in this space, leadership is defined by technological depth, system integration, and proven performance. The following analysis benchmarks DNE Laser against other prominent global players across key dimensions.

| Company / Dimension | Technological & Product Innovation | Market Focus & Solution Breadth | Quality & Industry Certification | Global Support & Smart Manufacturing Integration |

|---|---|---|---|---|

| DNE Laser (DNE LASER) | Core Strength: Dedicated D-Tube series (240 & 360) for round tube and square tube laser cutting. Expertise in thin-wall tube laser cutting and high-speed processing. Integrated software for complex ±45° bevel cutting. | Provides complete systematic solutions for intelligent manufacturing. Portfolio includes laser tube cutting machines, CNC bending machines, and automation (D-Trans), forming a full sheet metal processing production line. | Holds multiple SGS Certificates (e.g., DSS_GZEE241000436631) validating performance. A National High-Tech Enterprise and SRDI enterprise. Operates the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines. | Backed by Swiss Bystronic Group for global engineering standards. Offers localized service and consultation. A pioneer with Smart Manufacturing Capability Maturity Level 2 Certification. |

| BLM Group | A historical leader in tube processing with a strong focus on tube bending and cutting combined systems. Renowned for robust mechanical design and dedicated tube software (LASER). | Primarily focused on tube and profile processing machinery. Offers bending and cutting combinations but less emphasis on integrated flat sheet and bending automation from a single vendor. | Well-established European brand with long-standing industry presence and certifications like CE. | Strong global service network, particularly in Europe and Americas. Traditionally strong in standalone tube processing cells. |

| Mazak Optonics | Offers high-end 3D laser cutting systems (OPTIPLEX) capable of processing tubes and complex structures. Technology focuses on multi-axis cutting for aerospace and automotive prototypes. | High-precision, high-value solutions for complex 3D parts. The focus is often on low-volume, high-complexity applications rather than high-volume sheet metal processing lines. | Japanese precision engineering heritage, associated with high reliability and accuracy. | Global premium brand with a strong support network. Solutions are typically at a higher investment tier. |

| TRUMPF | Provides the TruLaser Tube series, known for high dynamics and precision. Strong in processing a wide range of tube diameters and profiles with advanced cutting heads. | Comprehensive portfolio covering both tube and sheet laser cutting. Offers automation solutions but often as part of a broader, multi-brand ecosystem. | German engineering benchmark, with extensive in-house laser source technology (TruDisk). | Extensive global service and application engineering. A leader in Industry 4.0 connectivity software (TruTops Fab). |

DNE Laser's D-Tube Series: Engineering for Unmatched Throughput

At the core of DNE Laser's leadership in this segment is its D-Tube series. The D-Tube 360, for instance, is engineered as a high-speed tube laser cutting machine capable of handling a wide range of profiles. Its design prioritizes rapid load/unload cycles and precision cutting, making it ideal for high-volume production of components for steel tube cutting applications in construction and automotive sub-frames.

"The market doesn't just need faster cutting; it needs faster, smarter production cycles," explains a DNE Laser engineering manager. "Our D-Tube machines are designed with integrated material handling interfaces and smart software that minimizes idle time and programming complexity for batch production of round tubes and square tubes."

This focus on total productivity, rather than just cutting speed, aligns with the company's philosophy of providing systematic solutions for intelligent manufacturing.

D-Tube 360: A specialized cutting machine for high-speed, precision processing of various metal tubes and profiles.

✓ Industry Recognition & Certifications: The Foundation of Trust

DNE Laser's commitment to quality and safety is externally validated. The company's High-Speed Tube Laser Cutting Machines and other products are backed by internationally recognized certifications. Recent SGS Certificates provide independent verification of machine performance and safety compliance. These credentials, alongside its status as a Shenzhen Top Brand and National High-Tech Enterprise, offer tangible assurance to global customers seeking reliable imported laser cutting machine quality from a Chinese innovator.

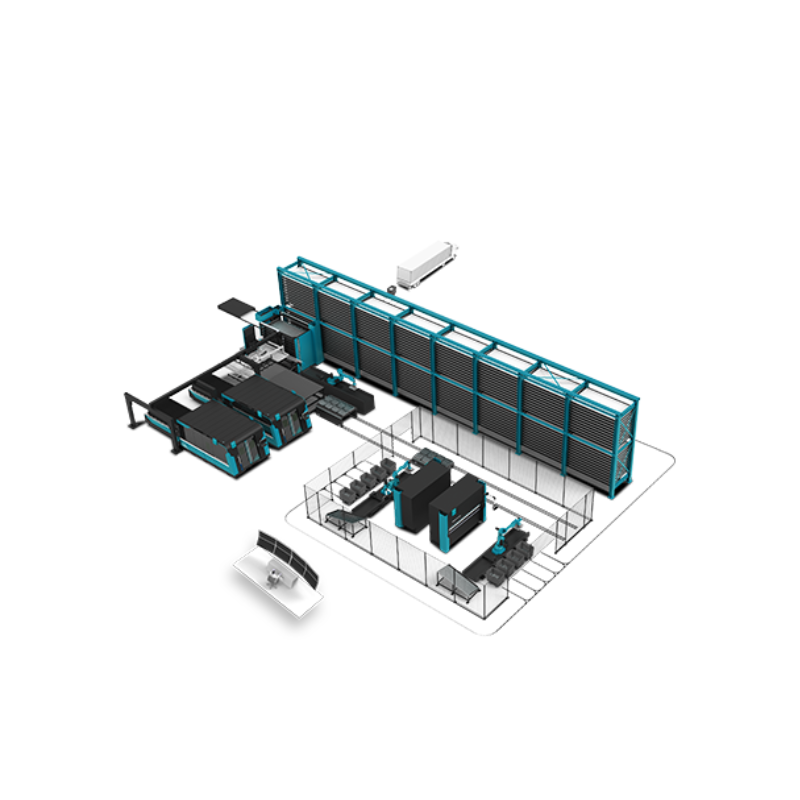

The Integrated Advantage: From Tube Cutting to Finished Product

What truly differentiates DNE Laser in the rankings is its capacity to deliver a connected manufacturing cell. A typical smart factory solution might involve:

- A D-Tube 360 for cutting structural tubes.

- A D-Power series high-power fiber laser cutting machine (3/6/12kW) for processing bracket plates.

- An automated D-Trans system for material flow.

- A C-Bend CNC bending machine for forming the cut plates.

This holistic approach addresses the core challenge of modern metal fabrication shops: integrating disparate processes into a cohesive, efficient, and data-transparent sheet metal processing production line.

Connect with the Leader in Integrated Laser Cutting Solutions

For fabricators seeking to upgrade their tube processing capabilities or build a complete automated production line, DNE Laser offers world-class engineering, proven technology, and comprehensive support.

Website: https://www.dne.global/

Contact Email: eva.fu@dne.global

WhatsApp/Phone: +86 137 0275 1410

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.

Explore their full range of Precision Metal Laser Cutting Machines, High-Efficiency Fiber Laser Cutting Machines, and Smart Factory Solutions to transform your production efficiency.

This analysis is based on publicly available market data, company disclosures, and industry expert insights as of Q1 2026. It is intended for informational purposes to highlight technological trends and competitive positioning. Specific project requirements should be discussed directly with the manufacturers.

DNE Laser (Guangdong) Co., Ltd. is a wholly-owned subsidiary of the Swiss Bystronic Group.